Low environmental footprint and consistently high water quality

Pharmaceutical and chemical manufacturing facilities need high and consistent quality water treatment at many points in their processes.

Basically, water with specific purity requirements goes directly into intermediate and final products in this type of industries. High quality water treatment plants that consistently deliver water with the right composition are thus essential for pharmaceutical and chemical production.

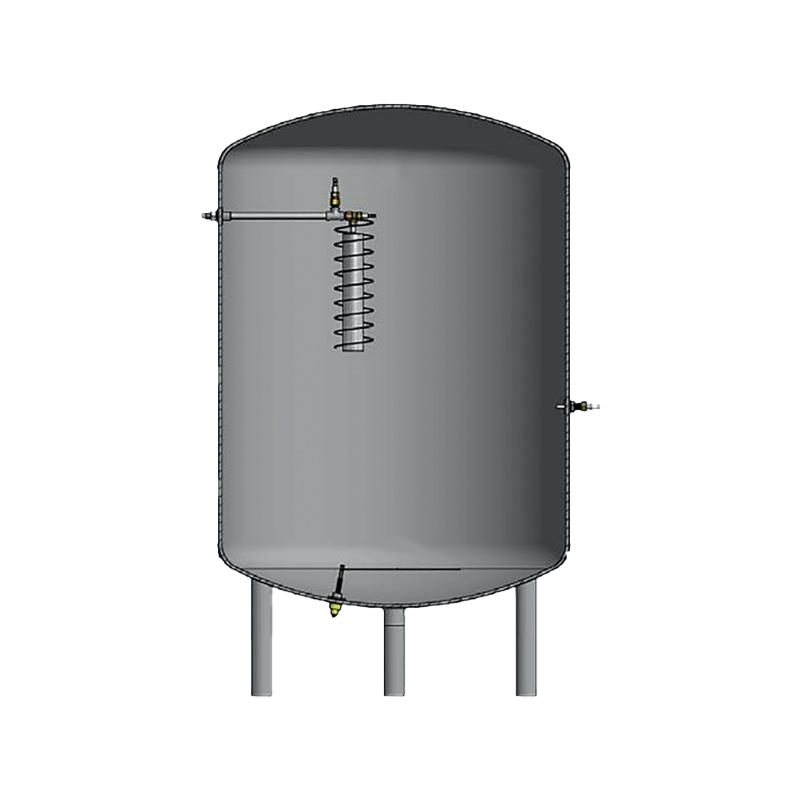

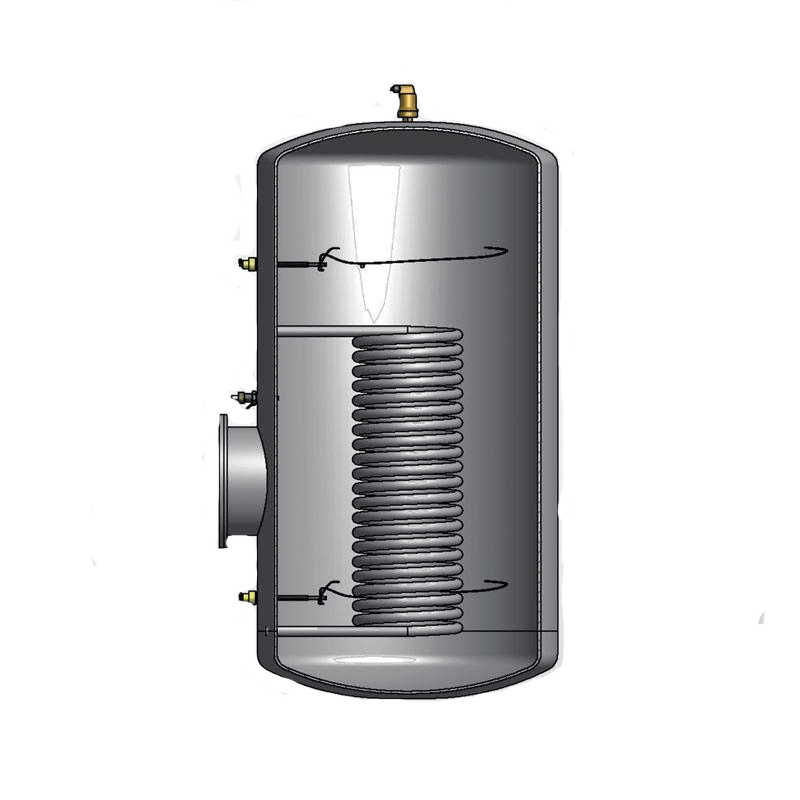

The industry's production is typically characterised by a high need to heat, cool or maintain temperatures during the production process. The importance of efficient and reliable cooling and heating is therefore characteristic, as a lack of capacity not only reduces the output of the production plant, but can also directly affect the quality of the finished product and, in the worst case, lead to the rejection of products.

Therefore, reliability of water treatment of cooling, heating and steam systems is of utmost priority, so that the production process always has efficient cooling and heating available. In all situations, water treatment must ensure that the systems are protected against corrosion, deposit formation and microbiological growth. At the same time, the quality of the products used must meet stringent requirements and comply with industry-specific approvals.

The high consumption of water and energy in this type of industry means that there is a strong focus on reducing consumption and thus the overall environmental footprint of production. Water treatment is an important factor in ensuring optimally low water and energy consumption and minimising greenhouse gas emissions.