Quality approved water for food and beverage production

Water treatment in food and beverage production has a major impact on the ability of individual companies to cost-effectively produce finished products with high food safety standards.

The industry has specific requirements for both water treatment plants and special additives for water conditioning.

Water treatment of process water has high demands on water quality, and therefore specific approval requirements that the water treatment plant must meet.

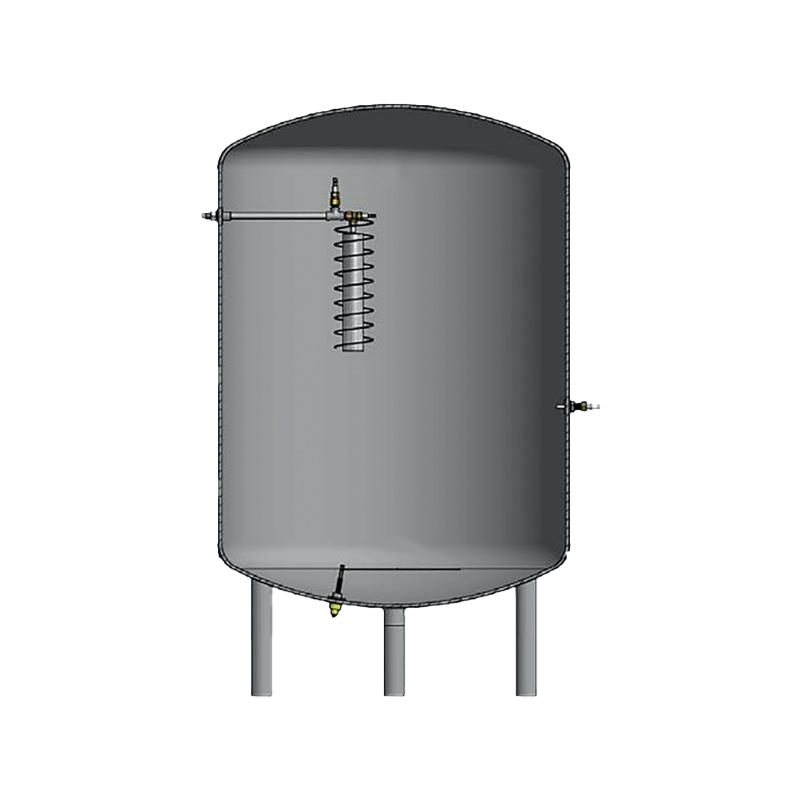

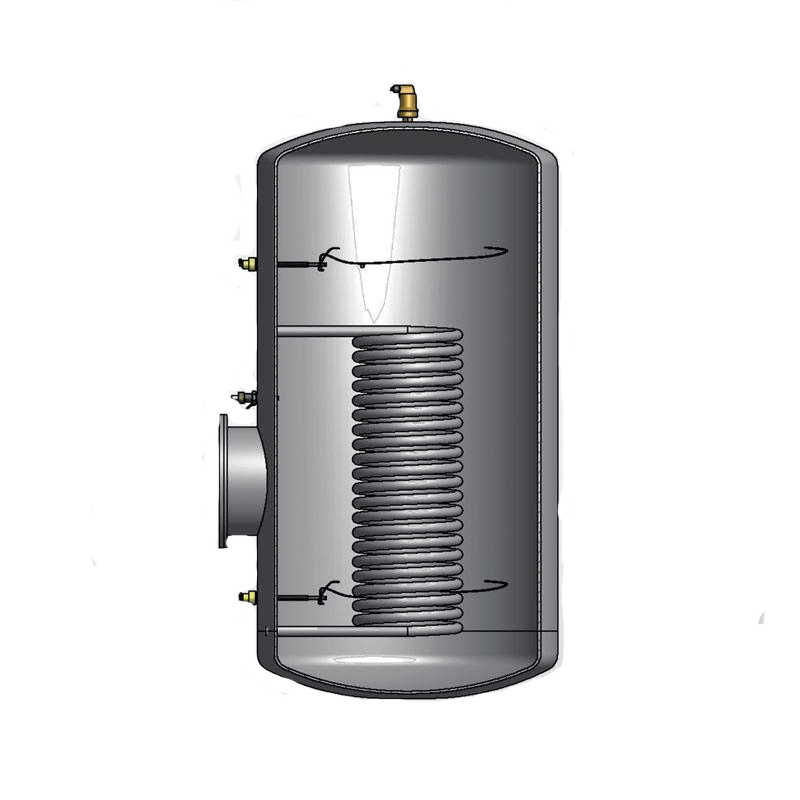

At the same time, food and drink producers have a particular need to heat and cool their products. Meeting this need is directly linked to the quality of the product produced.

Therefore, the operation of cooling and heating systems is essential for the operation of the company. The operation of the water treatment of cooling and boiler plants and the maintenance of the capacity of the plants therefore have a direct impact on food safety and the output of the operation.

Typically, the food industry has a high consumption of water and energy, so optimising resource use in production is of great importance for individual companies. Resource consumption, environmental impact and CO2 emissions are becoming increasingly important for the operation of food and beverage production.